The construction industry, long considered conservative and resistant to rapid technological change, is currently experiencing a quiet revolution. At the forefront of this transformation is 3D printing—or more precisely, additive manufacturing—applied to concrete construction. Once an experimental curiosity, 3D concrete printing (3DCP) is now proving its viability on real-world job sites, driving unprecedented changes in how we design, build, and envision the built environment.

Principles of 3D Concrete Printing

At its core, 3D concrete printing is a form of additive manufacturing in which a specially formulated concrete or mortar is extruded through a computer-controlled nozzle, layer by layer, to fabricate building components or even entire structures. Unlike traditional construction methods that rely on formwork, manual labor, and sequential trades, 3DCP automates the construction process, translating digital design files directly into physical reality.

There are two main technological approaches dominating the field:

- Gantry-based systems utilize a large frame, moving the print head along three axes to deposit material.

- Robotic-arm systems employ multi-axis industrial robots, providing greater flexibility for complex geometries.

In both cases, the process demands precise control over the rheology (flow characteristics) and setting time of the concrete mix, ensuring the material can be extruded smoothly and support subsequent layers without collapse or deformation.

Materials: Innovation Beyond Ordinary Concrete

Standard ready-mix concrete is ill-suited for 3D printing, as it is designed for casting and compaction rather than extrusion. As a result, much research has focused on developing specialized printable mixes. These typically feature:

- High viscosity and thixotropy to ensure shape retention after deposition

- Accelerated setting times for rapid build-up

- Carefully calibrated particle size distribution for pumpability

- Admixtures for workability, strength development, and shrinkage control

Incorporating fibers (such as steel, basalt, or polypropylene) enhances the mechanical properties and crack resistance of 3D printed elements, compensating for the absence of traditional reinforcement. Some advanced systems can even lay continuous reinforcement or embed post-tensioning cables during printing, further expanding design possibilities.

Advantages and Applications

The adoption of 3D printing in concrete construction offers multiple advantages over conventional methods:

- Freedom of Form: 3D printing enables the realization of complex geometries—organic curves, variable cross-sections, and intricate details—without the cost and labor of custom formwork. This expands architectural creativity and structural optimization.

- Material and Labor Efficiency: Automated deposition minimizes material waste, as structures are built only where needed, with no excess formwork or offcuts. Labor requirements are significantly reduced, addressing skill shortages and improving site safety.

- Accelerated Construction: 3D printed structures can be completed in a fraction of the time required for traditional builds. Projects that once took weeks can now be executed in days or even hours.

- Sustainability: Optimized designs use less material, and some systems utilize recycled aggregates or low-carbon binders, reducing the environmental footprint.

Applications are rapidly diversifying. Early projects focused on small houses and demonstration pavilions, but now include:

- Affordable housing units and emergency shelters

- Custom architectural facades and ornamentation

- Site-cast infrastructure components (retaining walls, benches, bridge elements)

- Complex formwork for casting high-performance concrete elements

Notable Projects and Industry Milestones

In recent years, several high-profile projects have demonstrated the real-world viability of 3D printed concrete:

- In the Netherlands, Europe’s first 3D-printed concrete bridge was constructed for cyclists, using robotic-arm technology to produce the span off-site.

- In Dubai, a municipal office building was printed on-site, covering over 600 square meters and achieving significant reductions in material and labor costs.

- In the United States and Europe, 3D printed homes have been completed and certified for habitation, proving that the technology can meet local building codes and occupancy standards.

These milestones signal a shift from pilot projects to mainstream adoption, attracting investment from major contractors, technology startups, and material suppliers.

Technical Challenges and Limitations

Despite its promise, 3D concrete printing faces significant challenges that must be addressed for broader adoption:

- Structural Reinforcement: Integrating traditional reinforcement (rebar) within printed elements remains complex. Solutions under development include embedding cables during printing, using steel fibers, or hybridizing with prefabricated cages.

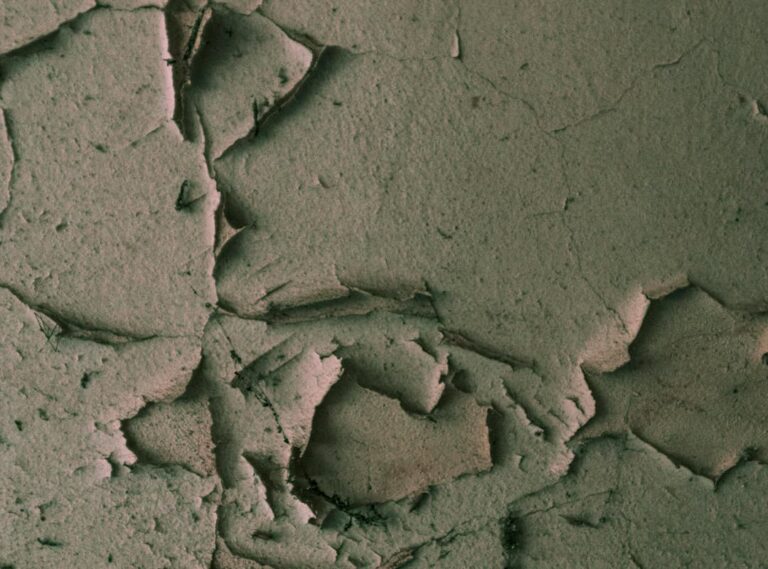

- Material Standards and Durability: Printable mixes must meet long-term performance criteria, including durability, freeze-thaw resistance, and fire safety. Establishing universal standards and codes is an ongoing process.

- Print Quality and Process Control: Variability in extrusion, setting time, and environmental conditions (temperature, humidity, wind) can affect print quality. Advanced sensors and real-time control systems are being developed to ensure consistent outcomes.

- Scale and Mobility: Printing very large or multi-story structures requires advancements in printer size, mobility, and on-site logistics.

The Future Outlook

The pace of progress in 3D printed concrete construction suggests that the technology is rapidly moving from the periphery to the core of the industry. As material science, robotics, and digital design continue to converge, the next generation of construction professionals will have powerful tools for realizing efficient, sustainable, and personalized structures.

Research is underway to further integrate 3D printing with Building Information Modeling (BIM), enabling seamless data flow from design to fabrication. Meanwhile, advances in automation, such as multi-material printing and autonomous site robots, may soon enable entire buildings to be constructed with minimal human intervention.

Conclusion

3D printing technologies are reshaping the future of concrete construction. By unlocking new design possibilities, streamlining processes, and addressing critical labor and sustainability challenges, 3D concrete printing is poised to become a cornerstone of 21st-century construction. While challenges remain, the remarkable progress to date signals that the future is not only possible—it is already unfolding before our eyes. Construction professionals who embrace these innovations will be at the forefront of a new era in the built environment.