Shrinkage is a natural process accompanying the strength gain of a concrete monolith, in which its volume decreases. Despite the insignificant indicators, the factor must be taken into account when calculating the ordered volume and the construction of any structures.

Types of shrinkage and the time during which it occurs

Non-experts believe that, given the quality and strength, thanks to which concrete of all grades has become the most popular building material, it is initially a “monolith”. In fact, concrete mortars have three “life cycles”, each of which is accompanied by a natural decrease in volume. This is called “concrete shrinkage”, which according to GOST should not exceed 3%.

The main causes of shrinkage are three: the presence of water in the ready-mix mortar, the process of hydration (formation of cement stone), and density gain (not to be confused with strength gain). Hence the three stages of volume reduction, shrinkage.

Plastic

From the moment water is added, it begins to bind to the cement, evaporate, flow away, etc. Before and after the concrete is placed. The higher the plasticity of the ready-mix concrete (more water), the greater the volume loss will be. In any case, moisture will be removed from the volume, so all grades of concrete are subject to shrinkage without exception.

This stage lasts 6-8 hours (primary setting) and gives the largest shrinkage ~4 mm per linear meter.

Autogenous

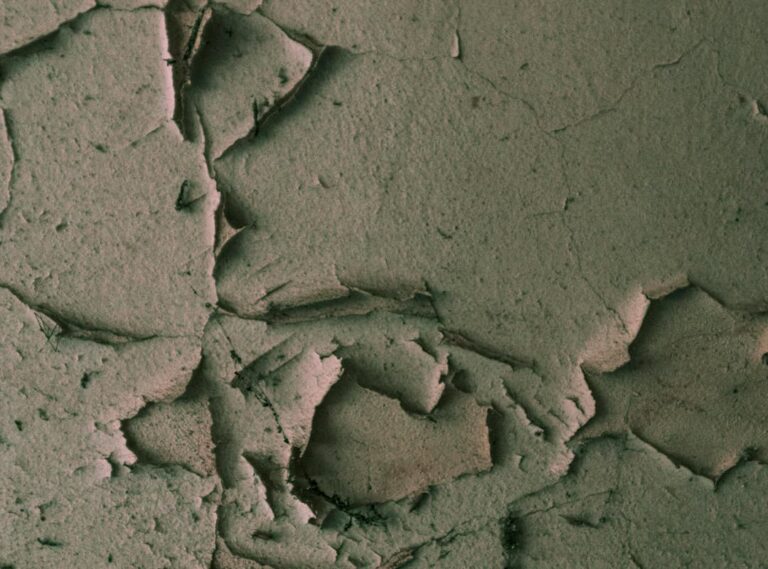

It starts from the moment of transition of primary hydration to the formation of strong cement stone. At this time, water binds, compaction begins (carbonization processes take place), excess moisture is forced out through capillaries to the outside or dries inside the monolith.

This stage lasts approximately 5-9 days, depending on the concrete grade. The total volume loss is ~1 mm per 1 p.m.

Contraction

Depending on the concrete grade and reinforcement, the rate varies between 0.2-0.8 mm per 1 p.m. It is associated with the natural compaction of the material, the departure of residual moisture and the final formation of cement stone. This is the final stage of the final set of strength and density of the concrete monolith, which lasts from a year to a year and a half.

Given the above, shrinkage processes and volume loss are not “force majeure”, but a predictable and calculated value that should be taken into account when ordering the required amount of mix.

How to calculate losses and reduce the shrinkage percentage

Let’s dispense with the intrigue, the practical value of the “additive” to the calculated volume of concrete mix is 8-10%. For the foundation – less, for the site – more. The reserve will take into account losses in transportation and pouring on site, as well as errors in the maintenance of the poured monolith, which is better to avoid.

In general, the calculation is based on plasticity and prediction of water loss. Therefore, the higher the plasticity index (mobility, maximum P5), the greater the shrinkage will be. But there are other ways to reduce volume loss:

- Reinforcement. The thicker it is, the less shrinkage there will be;

- Vibratory paving. Primary compaction during paving will reduce losses, even simple “poking” and tamping of the poured mixture will reduce them;

- Adding plasticizers and additives to the finished concrete mix to reduce volume loss;

- Reducing the amount of cement or sand (will affect strength);

- Using special grades of concrete that are not subject to shrinkage.