When planning a new roadway, parking lot, driveway, or industrial surface, the question of pavement material is among the most consequential decisions facing project stakeholders. Concrete and asphalt are by far the most common materials used in modern paving. While both offer reliable performance under the right circumstances, their physical properties, lifecycle costs, maintenance requirements, and environmental impacts are distinctly different. A clear understanding of these differences is essential to selecting the optimal surface for your project.

Material Composition and Construction Techniques

Concrete and asphalt pavements differ fundamentally in composition and installation. Concrete pavement is made from a blend of cement, water, aggregates (such as gravel or crushed stone), and, often, admixtures for performance enhancement. Once mixed, concrete is poured into forms, compacted, leveled, and finished before curing over several days.

Asphalt, by contrast, is produced by mixing aggregate with bitumen, a petroleum-derived binder. The hot mixture is spread and compacted in layers over a prepared base, and cools rapidly to allow quick opening to traffic. This difference in curing times often gives asphalt a scheduling advantage in fast-track projects.

Performance Characteristics

- Load Bearing and Strength

- Concrete pavements offer superior compressive strength and rigidity. This makes them ideal for heavy-duty applications such as highways, bus lanes, industrial yards, and airport runways. Concrete distributes loads over a wider area, reducing the risk of rutting or deformation under sustained traffic.

- Asphalt pavements are flexible and resilient, able to accommodate minor subgrade movements without cracking. However, under repeated heavy loads, asphalt is prone to rutting and shoving, particularly in hot climates or when improperly designed.

- Surface Texture and Skid Resistance

- Concrete can be finished to provide excellent skid resistance and surface drainage, and is often grooved or textured to reduce hydroplaning. Light-colored concrete reflects more sunlight, keeping the surface cooler and improving night-time visibility.

- Asphalt initially offers a smooth and quiet ride, but surface texture may degrade over time, leading to reduced skid resistance. Dark asphalt absorbs heat, which can contribute to urban heat island effects.

Durability and Lifespan

One of the primary distinctions between concrete and asphalt pavements lies in their long-term durability. Concrete surfaces routinely last 30–40 years or more with proper design and maintenance, sometimes exceeding 50 years in low-traffic environments. Asphalt pavements typically require resurfacing or major rehabilitation after 15–20 years, depending on traffic loading and climate.

The rigidity and chemical stability of concrete render it highly resistant to fuel spills, oils, and ultraviolet degradation, making it a preferred choice for areas subject to chemical exposure.

Maintenance and Repair

Maintenance profiles for concrete and asphalt diverge significantly:

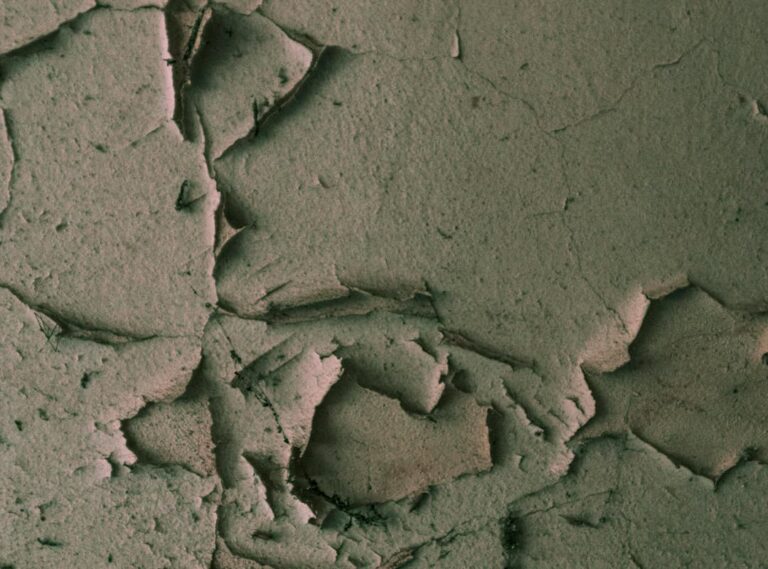

- Concrete pavements require less frequent routine maintenance but can be costly to repair if major cracking or faulting develops. Typical maintenance includes joint sealing and occasional slab replacement.

- Asphalt pavements demand regular sealing, periodic overlays, and patching to address cracking, potholes, or rutting. However, repairs are generally faster, less expensive, and can be completed with minimal disruption.

In regions with harsh freeze-thaw cycles, concrete may be more susceptible to spalling and surface scaling unless air-entrained mixes and appropriate curing techniques are used.

Construction Time and Traffic Disruption

Asphalt’s rapid cooling enables projects to be completed and reopened to traffic within a day or two, making it ideal for urban roadworks, overnight repairs, and areas with high traffic volumes. Concrete, due to its longer curing period, may require extended closures, although modern fast-setting mixes and precast slab systems are narrowing this gap.

Cost Considerations

Initial costs for asphalt pavements are generally lower than for concrete. Asphalt requires less upfront investment in both materials and labor, which is why it is often favored for large-scale paving projects with tight budgets. However, concrete’s lower lifecycle costs—owing to its longevity and reduced maintenance needs—can make it more cost-effective over the long term.

A thorough life-cycle cost analysis (LCCA) is recommended for major projects, taking into account initial construction, anticipated maintenance, downtime, and eventual rehabilitation.

Environmental Impact and Sustainability

Both materials have environmental advantages and challenges:

- Concrete is made primarily from abundant natural materials, but cement production is energy-intensive and generates significant CO₂ emissions. On the plus side, concrete is fully recyclable and, due to its light color, can reduce urban heat island effects.

- Asphalt is 100% recyclable, and reclaimed asphalt pavement (RAP) is commonly used in new mixes, reducing demand for virgin materials. Asphalt’s petroleum base, however, links it to fossil fuel extraction and greenhouse gas emissions.

In recent years, both industries have introduced innovations—such as supplementary cementitious materials in concrete and warm-mix technologies in asphalt—to mitigate environmental impacts.

Application Suitability

Choosing between concrete and asphalt depends heavily on the intended use:

- Concrete pavements excel in areas requiring longevity, heavy-load capacity, or high durability—such as highways, intersections, loading docks, bus lanes, airports, and high-traffic industrial settings.

- Asphalt pavements are often preferable for streets, parking lots, bike paths, residential driveways, and locations needing quick, cost-effective solutions or frequent reconfiguration.

Emerging Technologies

Technological advancements are blurring the traditional lines between the two materials. Ultra-thin whitetopping (placing a thin concrete overlay on existing asphalt) can extend pavement life. Polymer-modified asphalts and fiber-reinforced concretes are pushing performance boundaries in their respective fields. Smart sensors, recycled aggregates, and new binder chemistries further enhance sustainability and monitoring capabilities.

Conclusion

There is no universal answer to the concrete vs asphalt debate; the best choice is project-specific. Consider traffic loads, climate, project timeline, budget, maintenance resources, and sustainability goals. By understanding the strengths and limitations of each material, engineers and owners can ensure that their pavement investments deliver optimal performance and value over the structure’s full service life.