By definition, density is a scalar quantity indicating the ratio of the weight of a material to the volume it occupies. It is measured in kg/m³ (in the SI system) and g/cm³ (in the GHS system). Concrete is labeled in SI, denoted by the value D + a number. For example, D1500 means that a cubic meter of concrete weighs 1500 kg, and it is a lightweight composition.

For any body, density is directly related to strength, the most dense natural material is osmium (platinum group). The strength characteristics of this metal are exceeded only by artificially created materials. Do not confuse the relationship between density and hardness, the hardest element is diamond, which is related to the crystal lattice. At the same time, its density is 3,500 kg/m³, while osmium has 22,590 kg/m³, hence its super-high strength.

Despite the direct connection, the weight-volume characteristics of concrete are not paid enough attention, especially by private builders.

What is the density index and how it affects the properties of the monolith

In fact, the characteristic, sometimes called “specific gravity”, speaks about the amount of material in the volume under consideration. The ratio is always less than 100%, that is, there are air pores in a given volume that are not filled with the components of the concrete mixture. A denser monolith also has a stronger structure.

However, the indicator affects not only the strength.

- When air replaces other components in the structure, the overall strength of the monolith is reduced; displacement of pores increases it.

- The denser the concrete, the higher its thermal conductivity, especially heavy grades practically do not retain heat, and light, porous types of concrete are also used as heat insulators.

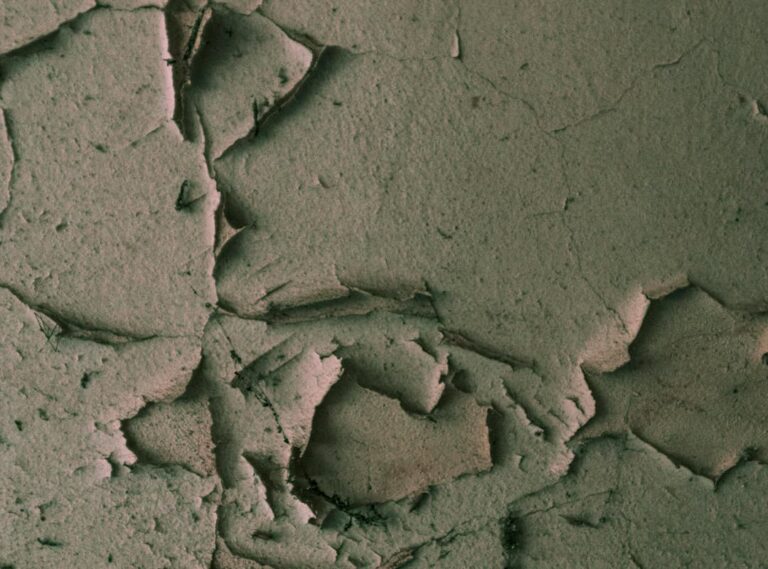

- Compacted monolith practically does not absorb moisture, does not react with it, which makes it possible to produce compositions for hydraulic engineering works. At the same time, frost resistance increases. Since there is no moisture in the volume, no defects occur during the “freeze-thaw” cycle.

- The denser the internal structure, the greater the resistance to tensile and bending loads. At the same time, the characteristic of compressive resistance (standard strength marking) can coincide with lighter concretes.

- It is clear that, as a result, the weight affects a wide range of properties, so the grade indicated in the documents for the batch is not decisive when choosing a mortar. Note that the weight of a cubic meter of mixture is a manageable value.

Increase the density can be increased during pouring, which will increase the strength of structures, by the following methods:

- Poking with shovels, rebar, etc. Air escapes from the pierced volume and the mixture is compacted. Suitable for small formworks;

- Application of vibrators. The mortar not only fills the reinforced space better, but is also deprived of air bubbles;

- Heating the monolith in the process of laying or pouring. The measure is not easy, but allows you to remove almost all pores from the volume.

These are technological measures that we recommend to carry out even when pouring typical concrete mixes on a private plot, even if you are pouring an ordinary floor screed.

It is easy to find out the density of the resulting solution. Weigh a liter jar, remember the weight, fill it with the mixture, stir it with a rebar and weigh it again. From the resulting figure, subtract the weight of the jar and divide by its volume (1000 cm³). Get the value in g/cm³. This will be the density of the resulting solution.

For example, the jar weighs 300 grams, and with concrete 2400. Simple calculation: 2400 – 300 = 2100, divide by 1000 = 2,1 g/cm³ or 2100 kg/m³. If the capacity is exactly 1 liter, you can simply take the difference in grams.

If the measures in laying allow a slightly higher specific gravity, a wider range of values is managed in production.